Welsh-Ryan Arena and Trienens Performance Center Renovations Achieve LEED Gold Certification

The Welsh-Ryan Arena and Trienens Performance Center renovation projects have achieved LEED Gold Certification from the U.S. Green Building Council (USGBC) on December 2nd, 2020, adding to the University’s impressive list of LEED-certified buildings. Leadership in Energy and Environmental Design (LEED) is a USGBC program that recognizes building designs that are resource-efficient and cost-effective, while providing a healthier and greener lifestyle for building occupants. The combined Welsh-Ryan Arena and Trienens Performance Center renovation project becomes the University’s 22nd LEED-certified facility.

“We are thrilled with this achievement,” said Senior Project Manager Steven Himes. “It was truly a team effort and could not have been accomplished without the full support of Northwestern Athletics, Northwestern Facilities, and architectural/engineering design and construction teams. This award is a testament to Northwestern’s continued commitment to sustainability.”

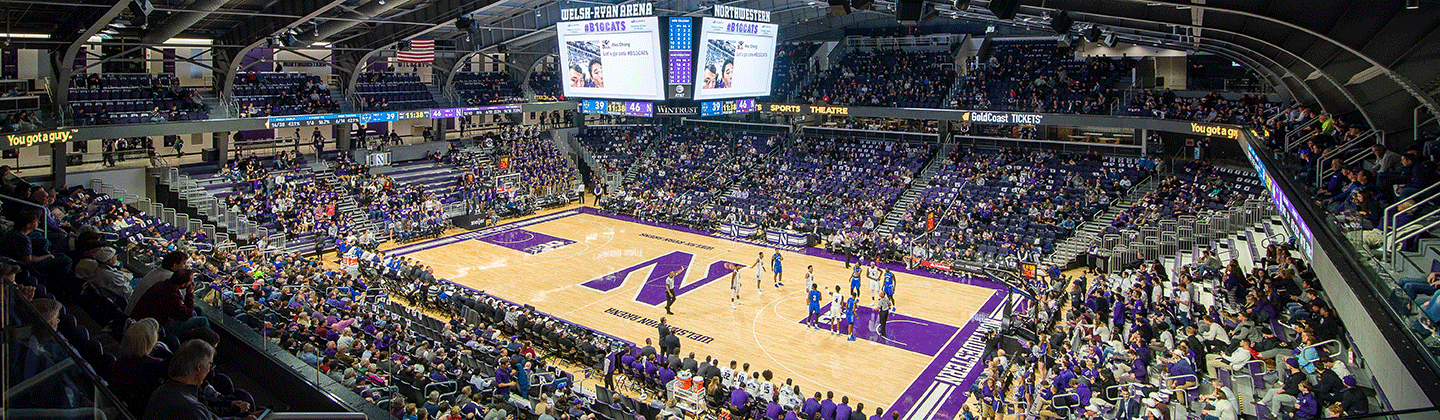

Welsh-Ryan Arena, which reopened in November 2018, is home to Northwestern’s basketball, volleyball, and wrestling teams. The arena underwent a 20-month, $118 million replacement of the exterior building enclosure and all interior spaces, including the seating bowl, fan amenities, and team locker rooms, as well as improved accessibility.

The Trienens Performance Center, which reopened the following year in November 2019, is an indoor student-athlete training facility located immediately adjacent to the arena and serves the basketball, volleyball, wrestling, baseball, and softball programs. The facility underwent a 16-month, $30 million renovation of the exterior building enclosure and all interior spaces, including the weight room, sports medicine area, and indoor practice areas.

From a sustainability perspective, the renovations included the installation of new mechanical, electrical, and plumbing systems, which optimize energy performance resulting in a more than 43% combined energy cost savings. Other sustainability features include:

- Diversion of more than 81% of construction waste from landfill

- Use of certified wood, regional materials, and recycled materials

- Water-conserving high-efficiency plumbing fixtures

- Use of natural light and high-efficiency LED lighting fixtures

- High-efficiency condensing boiler equipment

- High-efficiency air-cooled chiller equipment