The Kresge Climb

October 2014

Phase 1 of the Kresge Hall renovation involves interior abatement and demolition, as well as relocation and separation of mechanical systems servicing both Kresge and Crowe Hall.

Phase 1 of the Kresge Hall renovation involves interior abatement and demolition, as well as relocation and separation of mechanical systems servicing both Kresge and Crowe Hall.

To the East, facing McCormick Tribune, Kresge and Crowe Hall are connected via a two story building that once housed faculty offices. This area of the building will be demolished to accommodate a new state of the art five-story building housing new stairs, a modern elevator, faculty offices, presentation spaces and a basement to accommodate mechanical and electrical equipment.

On the exterior, a fence has been located around the building to separate the construction area from campus every day pedestrian traffic. Some trees had to be trimmed and others relocated around campus to make room for construction activities.

The existing stones dating back from 1955 will be salvaged for needed repairs to the existing façade around the building.

November 2014

Demolition continues at Kresge Hall

Demolition is completed on the third and fourth floors, and a portion of the second floor. Over Thanksgiving week contractors will start exterior demolition at the two story link between Kresge Crowe Halls.

←Most of the demolition at Kresge is done by two mini-backhoes with long arms that push masonry walls down to the floor. The same machines are then modified to become loaders that separate metals, cables, masonry, etc. for recycling. Since Kresge Hall will be a LEED certified building, each type of material has to be separated and transported in different dumpsters for recycling.

↑View of the fourth floor after the walls have been demolished. Only structural columns and exterior walls will remain.

December 2014

Demolition of the second story connecting Crowe Hall and Kresge Hall to the East was completed over the Thanksgiving break.

A demolition machine with giant hydraulic shears separated the stone from the metal. A giant crasher that looks like a dinosaur, removed the stone and concrete from the wall and a pulverizer crash the stone before they were transported of site on separate dumpsters.

At Kresge we recycle 1,703 tons of stone and concrete and 142 tons of metal. Less than 5% of the total debris that left the building was diverted to a landfill.

The next task in the project will involve taking down the existing concrete slab and foundations to make room for the new foundations, basement and concrete structure supporting the new fifth floor addition.

January 2015

The team

A complex project like the Kresge Hall Renovation requires a team effort. The architects from LVDA and consultants assembled a package of drawings and specifications for bidding. Five General Contractors were invited to submit proposals for the renovation. NU representatives from Facilities, architects, engineers and the bidders met at Kresge Hall for a site visit to get familiar with the project, proposals were submitted to NU.

After an extensive review of proposals and several

The drawings have been reviewed by the City of Evanston and approved by the Zoning and Preservation Departments.

February 2015

We started the year by reinforcing the existing columns on the North and South walls. The existing columns are not strong enough to support the new mechanical penthouse on the fifth floor. The perimeter columns are reinforced with steel bars and concrete while the columns located in the center of the building and the beams will be reinforced with multiple layers of graphite to keep them as thin as possible.

Here we see steel bars in place for column reinforcement prior to concrete placement.

Mini diggers are used inside the building to open tranches to accommodate underground piping. It took several weeks to saw cut the existing concrete slab, excavate the dirt, place new pipes, infill the trenches and finally pour a new slab on grade.

March 2015

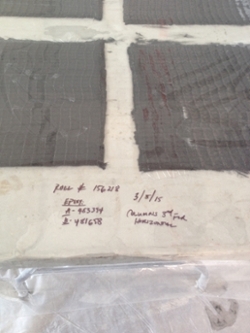

This portion of stone has been cleaned for review and approval. The architect, contractor, and FM staff review mortar color samples.

Deteriorated steel lintels will be replaced as the stone is prepared for tuckpointing and stone cleaning. Mortar grinding is almost completed on the North and West elevations.

← Excavation continues between Kresge and Crowe. The foundation for the addition has been designed and located away from the current foundations to avoid damage on the existing structures.

Metal sheeting has been pushed into the ground with hydraulic machines to keep vibration in adjacent buildings to the minimum. Workers will continue to excavate and install bracing to keep the sheeting in place.

Along the lane South of Crowe, a trench was excavated to accommodate new electrical service. The existing asphalt pavement has been temporarily patched to locate additional conduits in the ground. Over the summer, the pavement will be permanently restored and finished.

Along the lane South of Crowe, a trench was excavated to accommodate new electrical service. The existing asphalt pavement has been temporarily patched to locate additional conduits in the ground. Over the summer, the pavement will be permanently restored and finished.

Column reinforcement continues inside Kresge. Fiberwrap, consisting of a carbon reinforced fabric embedded in a fiber glass composite, was wrapped around columns and beams. These very thin layers will strengthen the existing structure and support the new fifth floor mechanical room.

Here, one of the samples is marked for weight/strength performance testing in the lab.

A new elevator will be located on the East side of the building and the elevator pit is now in place.

May 2015

Foundation walls were poured on the North and West sides of Kresge. After foundation walls are formed on the South and East sides, underground plumbing will be installed.

Foundation walls were poured on the North and West sides of Kresge. After foundation walls are formed on the South and East sides, underground plumbing will be installed. BAMR continues tuckpointing at North and West elevations. Each piece of stone is carefully removed from the wall, coded, restored and carefully repositioned in the same location. New steel dowels and the steel lintel hold the stone in place.

BAMR continues tuckpointing at North and West elevations. Each piece of stone is carefully removed from the wall, coded, restored and carefully repositioned in the same location. New steel dowels and the steel lintel hold the stone in place.New limestone lintels are a brighter white compared to old stone, so BAMR will clean the façade to make the color uniformed.

The roofing contractor is removing the old roof system and installing anchor bolts and grout to receive steel columns for the fifth floor penthouse which will house mechanical systems. A crane will be staged on the North courtyard to move the penthouse steel into place.

The roofing contractor is removing the old roof system and installing anchor bolts and grout to receive steel columns for the fifth floor penthouse which will house mechanical systems. A crane will be staged on the North courtyard to move the penthouse steel into place.By Spring a new white roof with an R-30 insulation value will replace the old system. The white roof will reduce the solar gain of the building and help save energy.

As of today, we have recycled 95% of the demolition debris and implemented an erosion and sedimentation control system to protect the site.

New Aluminum Clad Wood Double Hung windows will be installed and are made of Certified Wood. They have an excellent Solar Heat Gain Coefficient to help keep the building cool in the summer as well as save energy. (Sample, not actual window, pictured.)

On the third and fourth floors we continue to reinforce mechanical openings, install MEP (mechanical, electrical, plumbing) systems, VAV (variable air volume) boxes and ductwork, and hangers for IT cable trays.

On the third and fourth floors we continue to reinforce mechanical openings, install MEP (mechanical, electrical, plumbing) systems, VAV (variable air volume) boxes and ductwork, and hangers for IT cable trays. Above ceiling MEP work on the fourth floor is about 85% complete and we are very excited to start installing wall framing. Exterior wall construction will have an R-22 insulation value. All exterior walls will be insulated with sprayed-on foamed in place of polyurethane thermal insulation.

Our target is to use 100% low emitting materials (e.g. paint, flooring, composite wood adhesive, and sealant) and materials with a high recycle content, green certified, and from a local source, when possible.

We are reinforcing columns and beams to support the new penthouse and to cut large openings in the floors and roof to run mechanical systems. In some locations we use Fiberwrap in other locations old fashion steel beams.↓

June - July 2015

Starting in late June, one day after commencement, digging began outside Kresge and Crowe.

From mid-June through the end of July, electrical conduits, low voltage conduits, chilled and hot water lines were installed along the lane south of Crowe Hall.

From mid-June through the end of July, electrical conduits, low voltage conduits, chilled and hot water lines were installed along the lane south of Crowe Hall.

Three large manholes just outside Crowe, were placed with large cranes moving impressively between buildings.

Three large manholes just outside Crowe, were placed with large cranes moving impressively between buildings.

Structural steel is in place on the fifth floor and roof deck. Exterior walls will be coming in a few weeks. The HVAC contractor is currently installing the two air handling units as electricians continue to run conduits and wires inside walls and ceilings.

August 2015

HVAC workers continue to add and insulate pipes for the upcoming chilled sails and perimeter radiators. Kresge will be heated and cooled using the University’s highly efficient steam and chilled water system, which is as a result of upgrades at our central utility plant, located just east of Swift Hall.

The cooling will be provided by new radiant chilled sails ceiling system (very efficient!) and the ventilation systems will be upgraded throughout.

The cooling will be provided by new radiant chilled sails ceiling system (very efficient!) and the ventilation systems will be upgraded throughout. Exterior wall insulation has started on the third and fourth floor. Wall construction will have an R-22 insulation value. All exterior walls will be insulated with sprayed-on foamed-in-place of polyurethane thermal insulation. This will reduce the need for forced heating and cooling.